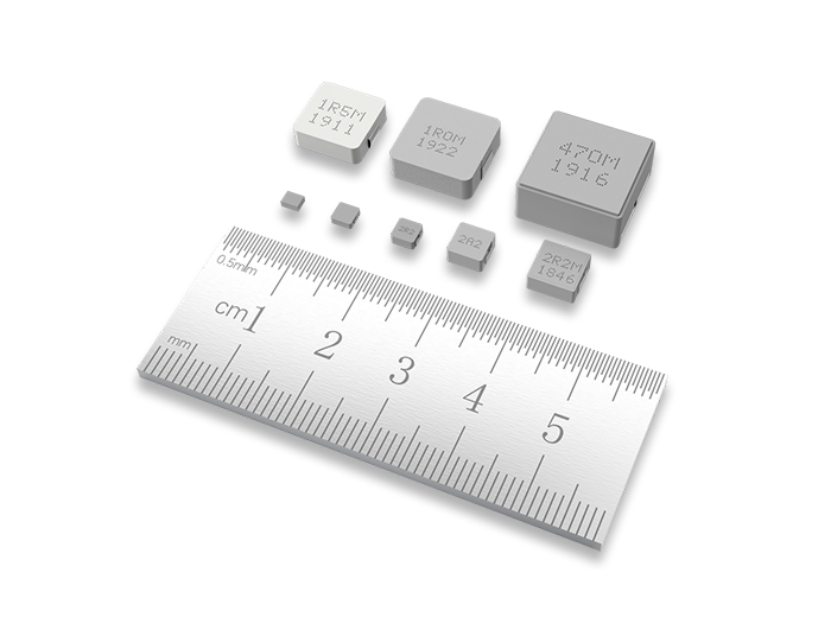

When exploring how a conductor and inductor influence power stability, many engineers begin by reviewing the basic behavior of magnetic components used in switching supplies. Companies such as Mentech develop these units for a variety of electrical systems, and they design them to match the operating frequency, thermal limits, and current requirements of modern equipment. In typical layouts, a conductor and inductor help manage energy transfer and reduce unwanted interference, which allows devices in communication, automotive, and renewable-energy sectors to function more consistently. Their purpose is not only to store energy but also to maintain current regulation during transient conditions.

How Inductor Design Supports Real-World Performance

To understand how a conductor and inductor behave under load, it is useful to look at a practical example. One of the components they produce is the MHA2213SG221M from their MHA2213SG series. This unit has a length of 22.5 mm, width of 22.0 mm, and height of 12.7 mm, offering an inductance of 220 μH with a ±20% tolerance. Its DCR rating is 103 mΩ while the Isat reaches 9 A and the Irms is 7 A. These values show how the component maintains stable current handling in compact layouts. Engineers working on automotive charging modules, energy storage interfaces, or communication devices often rely on similar structures because the magnetic path and winding configuration can be optimized to meet thermal and electrical limits.

Application Considerations in Different Industries

Different industries evaluate a conductor and inductor according to their own requirements. Automotive and new-energy devices often prioritize thermal endurance and structural stability, while communication equipment focuses on signal integrity and noise control. They provide components for power modules, OBC and DC-DC systems, micro-inverters, and network equipment, ensuring compatibility with existing design standards. Because Mentech maintains a broad category of magnetic parts, engineers can review multiple options in one place without shifting between suppliers. Their long-term manufacturing experience, in-house tooling capability, and automated lines support projects that require predictable quality and consistent lead times.

Conclusion: Selecting Magnetic Components with Confidence

In summary, selecting the right conductor and inductor depends on understanding how the device behaves within the target application. Examples such as the MHA2213SG221M illustrate how specific electrical parameters guide component choice. As they continue to support communication, automotive, and new-energy customers, Mentech offers magnetic parts that match diverse industrial needs. Their vertical integration, engineering resources, and established operational background allow them to supply solutions that fit both development and production requirements.