As demand for energy storage batteries continues to rise, manufacturers must invest in efficient and reliable manufacturing equipment. Understanding the various types of equipment available is crucial for optimizing production processes and ensuring high-quality output. This guide highlights key considerations when selecting manufacturing equipment for energy storage batteries, with an emphasis on enhancing battery manufacturing efficiency.

Types of Manufacturing Equipment

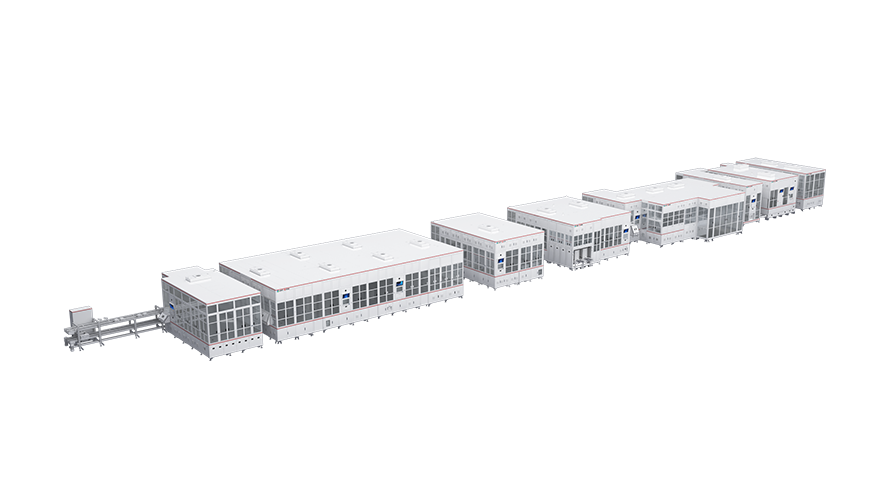

When exploring manufacturing equipment for energy storage batteries, various types must be considered. An automatic assembly line designed specifically for aluminum can batteries stands out as a key component in modern battery manufacturing. This type of equipment offers high compatibility, making it suitable for mainstream M6U process cell production. With an impressive efficiency rate exceeding 24PPM (pieces per minute), this assembly line significantly enhances production capabilities while ensuring consistency in output.

Importance of Process Optimization

Optimizing production processes is essential for effective battery manufacturing. The integration of advanced technologies, such as automated assembly lines, allows for streamlined operations and the reduction of labor costs. Automated systems not only improve efficiency but also minimize human error, ensuring that each step in the battery manufacturing process is executed with precision. By leveraging the right equipment, manufacturers can boost their overall productivity and enhance the quality of their energy storage batteries.

Focus on Quality Control

Quality control is paramount in battery manufacturing, as it directly impacts the performance and safety of energy storage solutions. Implementing rigorous quality assurance measures throughout the production cycle helps identify and mitigate potential issues. Utilizing specialized manufacturing equipment equipped with inspection and testing capabilities ensures consistent quality in every batch of energy storage batteries produced.

For manufacturers aiming to excel in the energy storage market, investing in the latest manufacturing equipment is critical. Partnering with reputable suppliers like Yinghe, known for their advanced solutions in battery manufacturing, will enable companies to optimize their production lines and meet growing consumer demands efficiently. By focusing on technology, optimization, and quality control, businesses can ensure they are well-equipped to thrive in the competitive landscape of energy storage batteries.